DON'T COMPROMISE

DISCOVER THE FUTURE OF ENVIRONMENTALLY FRIENDLY PERFORMANCE OUTERWEARKnown for being PFAS-Free* since its inception and it's exceptional waterproof and moisture vapor transmission (mvt) ratings, InderShield™ has paved a new path for performance waterproof-breathable textiles, bringing top performance ratings and sustainability together.

InderShield's proprietary PU membrane and uniquely optimized construction make it the most innovative waterproof-breathable material we've seen yet.

Keep scrolling to discover how InderShield™ offers durable, waterproof-breathable performance at the highest level while being PFAS-Free*.

*No intentionally added per- and polyfluorinated substances

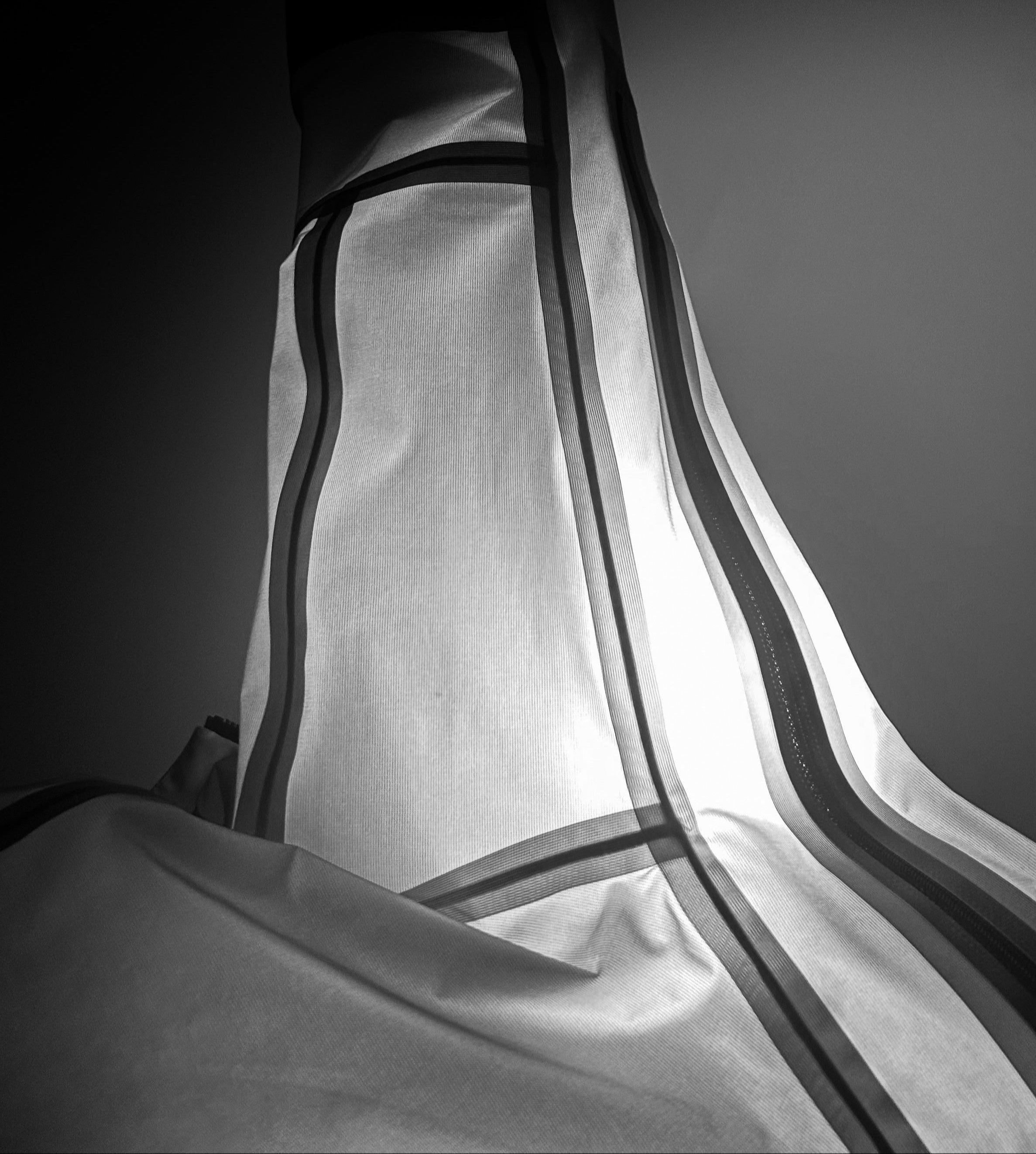

InderShield™ is a three-layer laminate made from a proprietary PU membrane, a durable nylon face fabric, and a nylon backer.

We've optimized everything from the membrane's performance and face fabric's weight, to how we're gluing and laminating the material into its final form, to create what we believe is the optimal balance of waterproofness and breathability for a rugged shell material.

Sustainably and Durably Waterproof

40,000mm waterproof ratingInderShield™ Rugged's 40,000mm waterproof performance is a function of its entire three-layer system. At its core, InderShield™'s proprietary PU membrane creates a durable barrier preventing water from getting through, keeping you dry. In addition to the membrane's performance, we've optimized the gluing and laminating construction for optimal waterproof-breathable performance in a rugged shell.

In our final construction, InderShield™ Rugged has a 40,000mm waterproof rating following the JIS & ISO standards.

Explore InderShield™ Rugged Products

The Pinnacle of Storm Protection for the most severe weather conditions

Remarkably Breathable

30,000g MVT ratingInderShield™'s proprietary polyurethane membrane has a monolithic structure that passes moisture vapor through at an incredibly rapid rate on its own.

In our optimized three-layer construction for extreme conditions, InderShield™ Rugged allows moisture vapor to pass through at a rate of 30,000g/m2/24hr.

Having strong mvt performance ensures moisture vapor can escape during intense activities, which is critical for your comfort and safety in all environments.

Windproof

Having a windproof shell is another necessity. InderShield™'s membrane blocks wind from penetrating the shell, keeping you protected from harsh storm conditions.

Testing

You need to trust your gear when it counts, which is why we put all of our products through rigorous testing before ever releasing them to you. From extreme waterproofness to extreme breathability, we develop and test products you can trust in the most severe weather conditions.

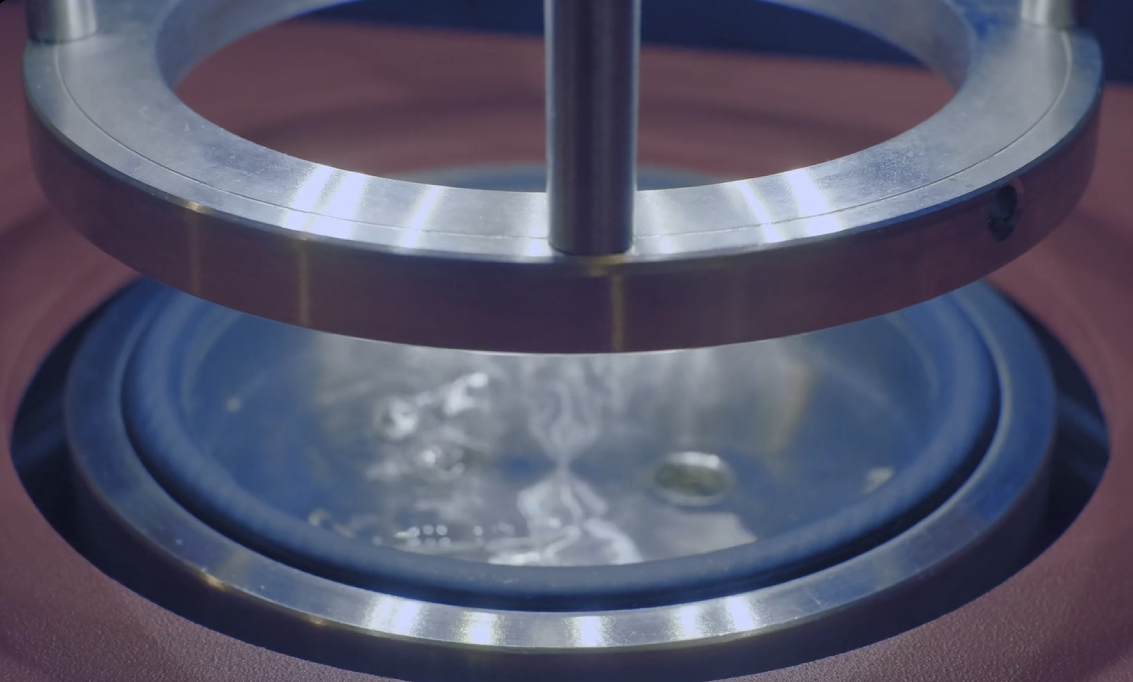

1. Lab Testing

All of our products start in the lab. Water resistance, moisture vapor transmission, spray, and killer attack wash are just some of the tests we use to determine a material's performance. We set performance targets that the material must hit before being passed on to storm testing.

2. Severe Storm Testing

After a material hits our lab testing targets, we test it in unimaginable storm conditions. In our rain chamber, we simulate storms more extreme than the most severe weather the material is intended to withstand. This proves the material's performance in a garment enduring the harshest of weather conditions.

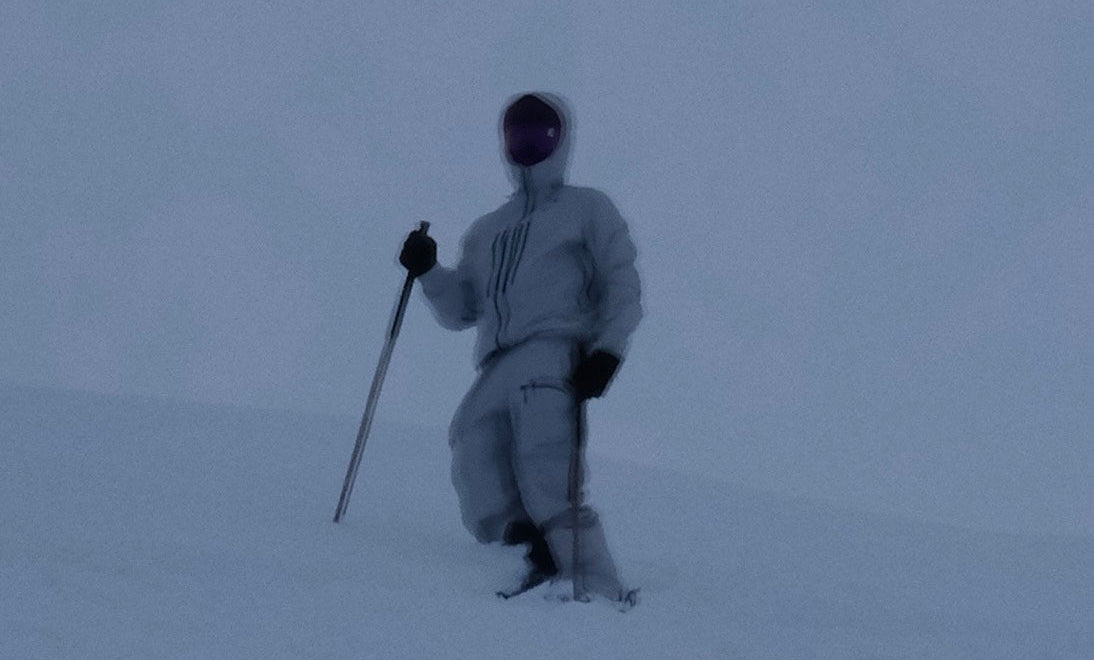

3. Field Testing

Once the material has proven itself in the lab and in severe storm conditions, it's time to bring it into the field. We work with professional athletes who spend all year pushing our gear to the limit.